Tab Terminal

Regarding Tab Terminal

Tab terminal is enacted in Japan Industrial Standard "JIS C 2809 Flat quick-connect terminations" consistent with the international standard "IEC 60760 Flat quick-connect terminations". Because Rrhythm's tab terminal conforms to this, it can conform to the receptacle (connector) of each manufacturer and can connect it.

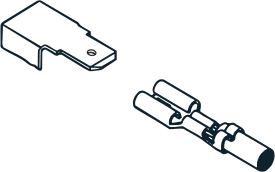

Regarding low fitted receptacles (connectors) compatible products

There are receptacles (connectors) that reduce the insertion force when engaged and has a locking function with a spring lever etc. There are tab terminals that require wider space than the standard because of its structure, so please refer to the product specifications when using.

* For details, please refer to the tab terminal specifications in the separate table

★ Example of low fitting receptacles (connectors)

- Tyco Electronics Japan G.K.

Positive Lock Connector Series - J.S.T.MFG.CO.,LTD.

PS connector series

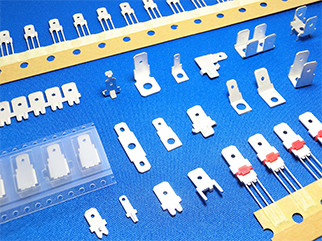

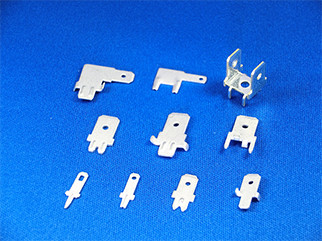

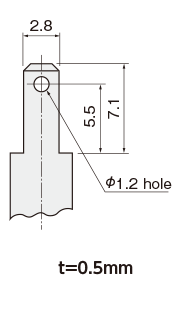

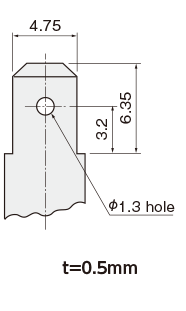

Series of Tab Terminals

The series of the tab terminal, together with the receptacle (connector)

There are 110 series (JIS 2.8 mm), 187 series (JIS 4.8 mm) and 250 series (JIS 6.3 mm).

We have 205 series in addition to this as our standard product.

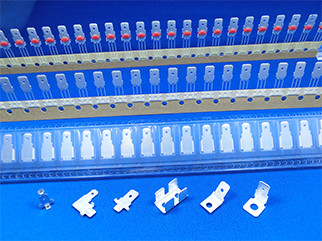

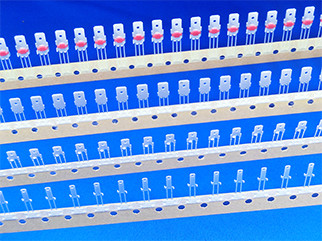

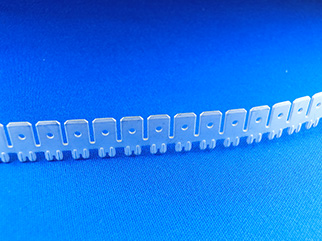

Packing type

Plastic bag packing

Radial lead taping

Embossed taping

Reel packing

Specification of Tab Terminal

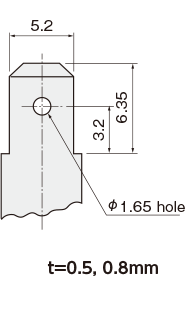

| 仕様 | 110 series(JIS 2.8㎜) | 187 series(JIS 4.8㎜) | 205 series | 250 series(JIS 6.3㎜) |

|---|---|---|---|---|

| Tab terminal fitting part shape |

|

|

|

|

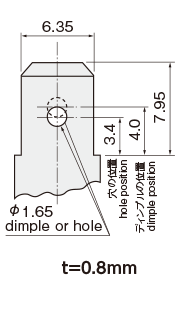

| Low fitting receptacle(connector)corresponding tab Terminal fitting part shape |  |

|

||

| RatingMaximum current value when wire size to be crimped and temperaturerise value are set conditions |

|

|

|

|

| For pc board Plastic bag packing |

○ | ○ | × | ○ |

| For pc board Reel packing |

○ | ○ | × | ○ |

| For pc board Radial lead taping |

○ | ○ | × | ○ |

| For pc board Embossed taping |

× | ○ | × | × |

| Other Plastic bag packing |

○ | ○ | ○ | ○ |

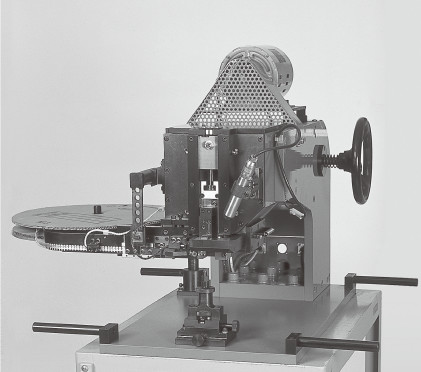

TAB INSERTER “IM-101B”

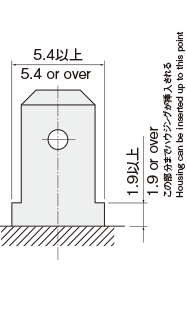

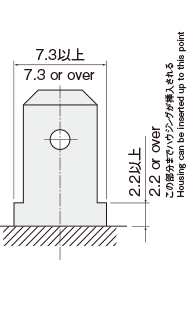

Tab terminal inserter is a machine for inserting and attaching chained reel tab terminal to printed circuit board.

Applied by the above tab terminal for printed circuit board mounting use (reel packing)

Features of TAB INSERTER

A single axis cam mechanism is provided for smoother, and more reliable feeding, severing, and inserting of the strip tab terminals。

The applicator to be adaptable to tab terminals is unitized for easier changes of any tab terminals used.

Locating light is provided for easier positioning of the printed circuit board at an accurate insertion point.