RHYTHM VIETNAM (SAIGON) CO., LTD.(RVS):EPE(Export Processing Enterprises)

The products made by our experienced Vietnamese staff are now widely used in automobiles, motorcycles, solar power generation, home appliances etc...and are exported to countries around the world, including Vietnam.

In addition to stamping products, we also design and manufacture stamping dies,

insert molding parts, winding coils and assembly parts. Moreover, we have our own plating line, which enables us to cover the entire process from stamping raw materials through plating on those surface and assembling into modules.

In the end of 2023, our factory 1 completed and activated our first solar panel installation. It generates approximately 500,000 kWh per year, representing approximately 10-12% of our total annual electricity usage.

※We have changed our company name from KYOSHIN VIETNAM CO., LTD. to RHYTHM VIETNAM (SAIGON) CO., LTD. effective April 2025.

Our Business

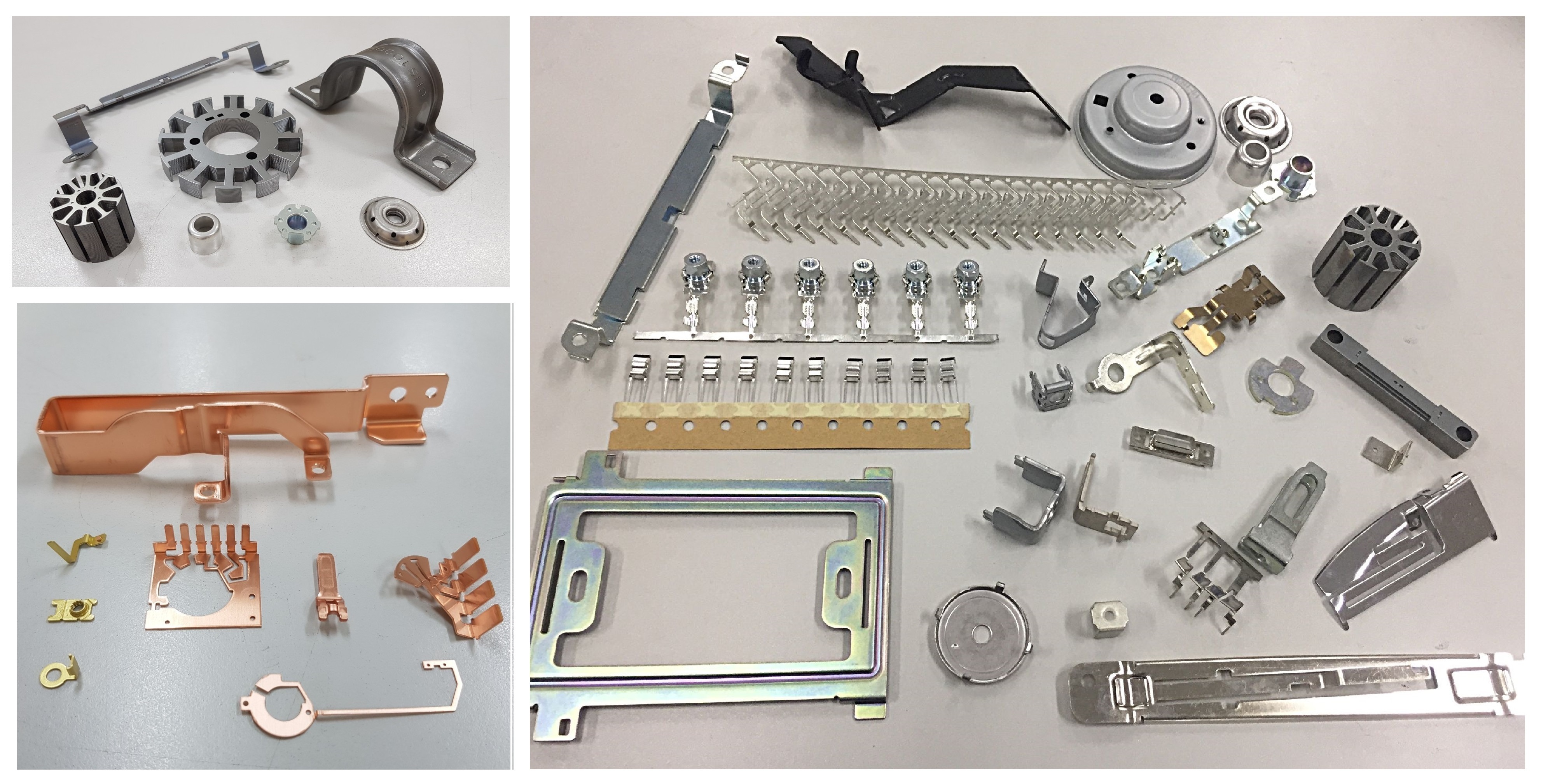

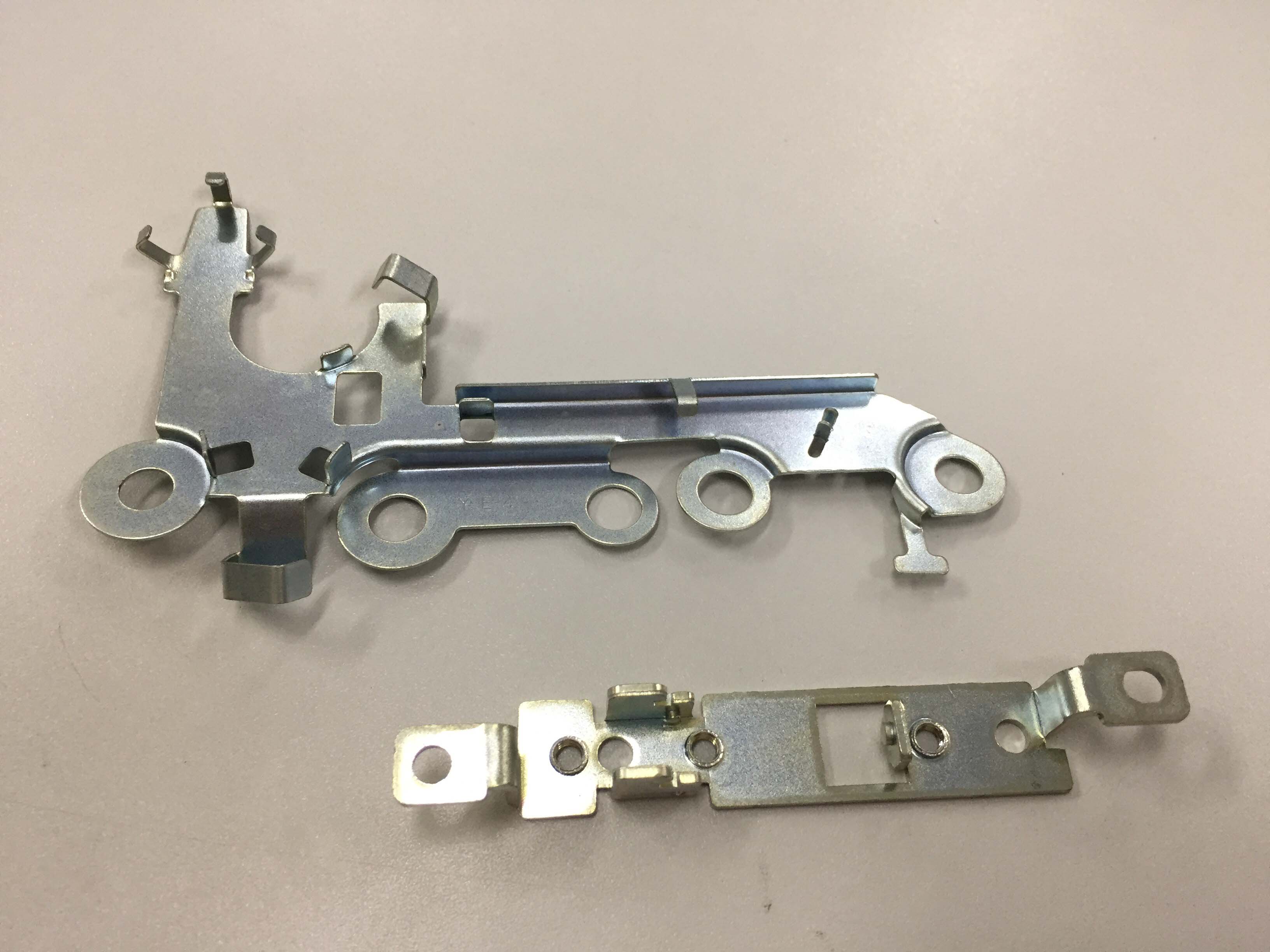

【Progressive Metal Stamping Parts】

We provide an integrated one-stop service, covering everything from the design and machining of metal stamping dies to the manufacturing of progressive stamping parts.

Our facility is equipped with 24 stamping machines ranging from 25 to 220 tons, and we specialize in precision stamping work suitable for palm-sized components.

We can produce a wide variety of shapes for diverse applications, including drawn products, terminals, busbars, yokes, plates, holders, brackets, elements, laminated cores, clamps, retainers, and calipers.

Progressive in-die tapping and in-die riveting/crimping are also available.

■Product samples

■Raw Material of Products

Cold rolled steel(SPCC、SPCE、SPCF)

Electro-zinc coated cold rolled steel(SECC)

Galvanized Cold Rolled Steel(SGCC)

ZAM

Non-Oriented Electrical Steel

Soft Magnetic Iron(SUYP)

Stainless Steel(SUS304、SUS410、SUS430)

▶Non Ferrous Matals

Aluminium(A1100)

Brass(C2600,C2680、C2801)

Phosphor Bronze(C5191、C5210)

Tough Pitch Copper(C1100)

Oxygen Free Copper(C1020)

Corson Alloy(C7025)

Cu-Mg(MSP1)

Cu-Fe(TAMAC5)

※For non-ferrous metals, both bare materials and plated materials (tin reflow, tin, nickel, gold, silver) can be available.

t0.1mm~t3.2㎜

■Raw Material Maker(direct or indirect)

▶Steel

CSVC(China Steel Sumikin Vietnam)

POSCO(Vietnam/Korea)

JFE Steel(Japan)

Nippon Steel(Japan)

Kobe Steel(Japan)

Nippon Kinzoku

Create Steel(Taiwan)

▶Non Ferrous Metals

Mitsui Sumitomo Metal Mining(Japan)

Mitsubishi Material(Japan)

JX Metal(Japan)

Harada Metal(Japan)

Sugino Metal(Japan)

Uji Copper & Alloy(Japan)

Minchali(Taiwan)

First Copper(Taiwan)

Poongsan (Korea)

Lee Ku(Korea)

Siam Poongsan(Thailand)

【Progressive Stamping Dies】

Rhythm Vietnam (Saigon) has designed and built over 800 progressive dies in the past.We are capable of producing large dies up to 1500mm in length. (Max. 220 tons for press machine)

Drawing, terminals, busbars, brackets, lamination cores, in-die tapping and in-die caulking/rivetting are all produced in-house.

A total of 20 members in the die making team perform design, machining, assembly, trial, and adjustment.

Our basic policy is to build 100% of the stamping dies we receive orders from our customers in-house. However, in cases where a large number of dies need to be produced at once, we may outsource processing to a third party in order to prioritize lead time.

※We select outside processing contractors that are capable of producing molds in accordance with our design and processing standards.

■Materials for Dies

SDK11、SKS3、C45、Carbide

■Material Maker

FUTABA(Vietnam)

DAIDO(Vietnam)

Pro-Vision(Vietnam)

Sanaloy(Thailand)

■Standard Punches Maker

Standard punches: Misumi(Vietnam)

Irregular shape punches: In-house

【Surface Treatment】

We are one of the few press shops that can handle electro plating (reel-to-reel plating and barrel plating) in-house.We are trying to shorten the lead time and stabilize the quality by doing integrated production from metal stamping to plating in-house.

Press materials include oxygen-free copper, tough pitch copper, brass, phosphor bronze, Corson alloys, cold-rolled steel sheets, and Soft Magnetic iron.

Plating quality evaluation includes plating thickness test, peel test, salt spray test, and solderability test.

We can provide daily plating solution management, periodic plating solution analysis, and various environmental surveys of plating chemicals.

We are taking all possible measures to comply with the environmental regulations of the authorities regarding wastewater treatment and auditing.

For other surface treatments, we use external subcontractors. See below.

■In-house Plating

Nickel(Ni)、Tin(Sn)--- all by electro plating

Applicable material thickness for reel-to-reel plating: t0.2 mm to t1.2 mm

Applicable material width for reel-to-reel plating:Max50㎜

Cu(Base)+Ni、Cu(Base)+Sn、Ni、Sn、Cu(Base)+Ni(Base)+Sn、Ni(Base)+Sn

Various combinations are available.

For reflow tin, please contact us.

Copper(Cu)、Nickel(Ni)、Tin(Sn)--- all by electro plating

Cu(Base)+Ni、Cu(Base)+Sn、Ni、Sn、Cu(Base)+Ni(Base)+Sn、Ni(Base)+Sn

Various combinations are available.

In many cases, the finish of the plating is specified on the drawing as bright, semi-bright, or non-bright.

Each customer has different standards and judgments regarding the quality of these finishes ( brightness).

Since it is not possible to adjust the brightening agent in the plating solution tank for each customer's specifications, we judge whether the plating tank is brightened or not by adding a brightening agent.

※We will consult with you in advance about any brightness issues and take necessary measures such as limit sample management.

■Subcontract plating (subcontractors)

▶Barrel Plating

Electroless nickel plating、Zinc Chromate Plating

※Please ask us about the finish color of zinc chromate plating.

▶Rack plating (hanging plating)

Electroless nickel plating、Zinc Chromate Plating

※A special hanging jig (hanger) may be required depending on the part shape.

※Please ask us about the finish color of zinc chromate plating.

▶Cationic ED Coating

We can make a hanging jig (hanger) that matches the shape of the part.

In cationic ED coating, jig marks (areas where no coating is applied) are always left on the parts that are exposed to the hanging jigs (hangers).

We will consult with you in advance about the area where the jig will be hooked.

【Vacuum heat treatment, Magnetic annealing】

Magnetic annealing treatment are available for ferrous material parts after metal stamping.

Set the workpiece→Heat up→Holding at about 850°C→Cooling→Take out the work

Nitrogen gas can be used to control cooling, allowing for rapid or slow cooling within a specified time.

It is convenient to set with plating after magnetic annealing.

We keep annealing temperature charts for traceability.

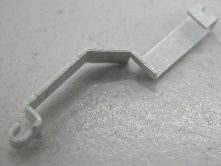

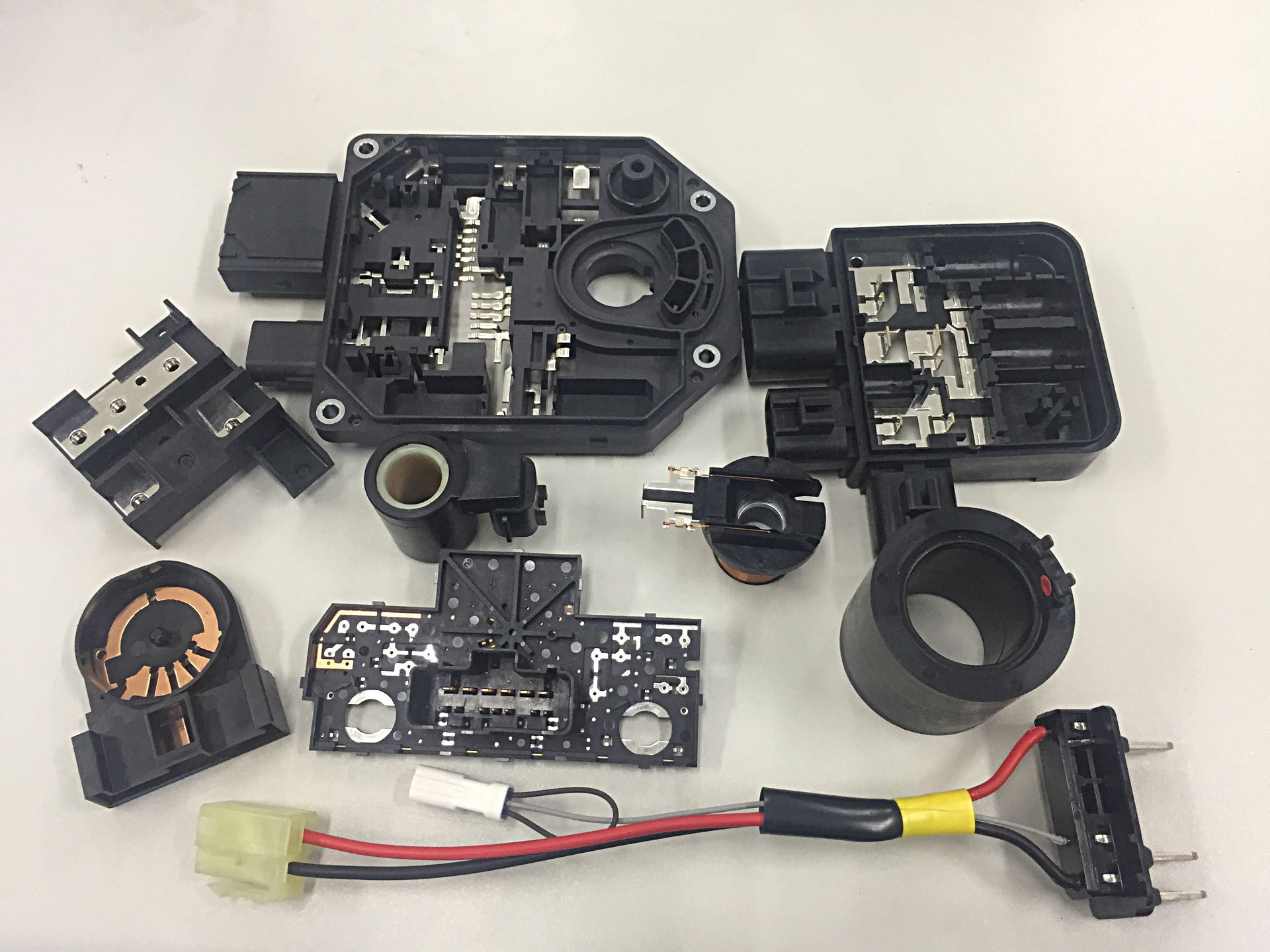

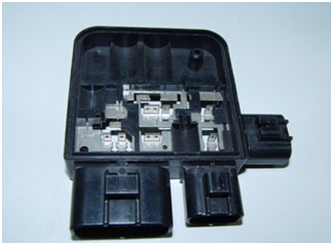

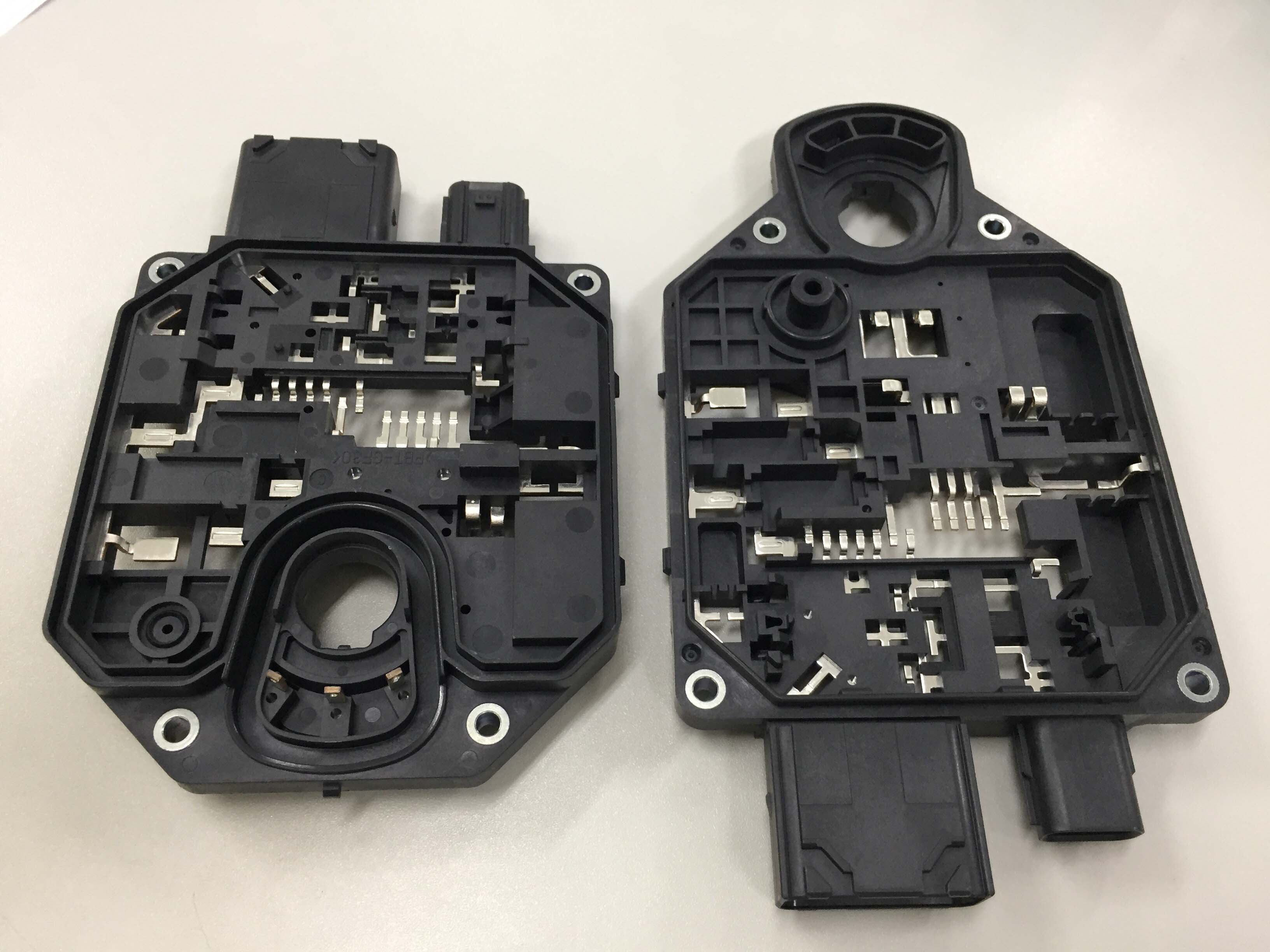

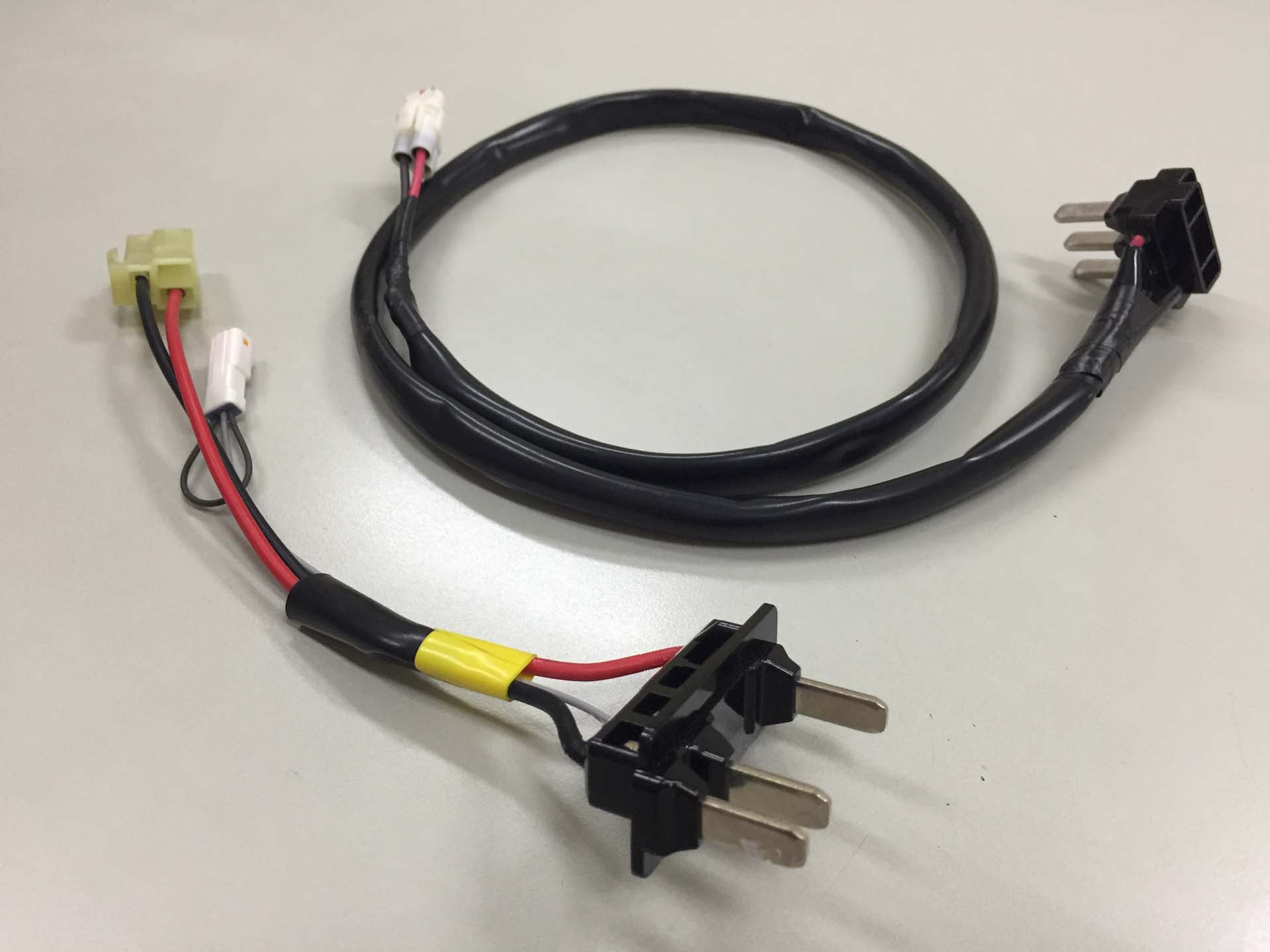

【Over Molding/Insert Molding】

We perform over-mold various stamping parts (materials include oxygen-free copper, tough pitch copper, brass and cold-rolled steel sheets) that we process ourselves, machining parts that we purchase from outside, and nuts.

We have a total 19 vertical injection molding machines ranging from 40 to 150 tons.

After molding, tie bar cutting, conductivity testing, air leakage testing, water leakage testing, and filter welding are also available.

Material:PBT GF40

Application:

Air conditioner switch for Automotive

Material:PBT GF40

Application:

Radiator fan motor for Automotive

Material:PBT GF30

Application:

Radiator fan motor for Automotive

Material:PC

Application:Motor Assisted Bicycle

■Plastic Regin

PA6

PA66

PA46

PBT

POM

ABS

PPS

LCP

PC

■Resin Maker(direct or indirect)

Toray

Polyplastics

Mitsubishi Engineering Plastics

Ube

DSM

Asahi Kasei

DIC

Kuraray

Toyobo

▶In-House(Kyoshin Vietnam)

We design and build mainly renewal molds for over-molding parts.

▶Outsource(Subcontractors)

We outsource insert molding dies by utilizing the group's resources.

①Aizu Factory, Rhythm Co., Ltd.

②Rhythm Precision Vietnam

In addition, we have subcontracted the production of molds for less difficult parts to a partner company in Vietnam.

【Solenoid Coils】

We produce winding coils (solenoid coils) mainly used for various solenoid valves in automobiles.

These are assembled into EGRV(Exhaust Gas Recirculation)、VTC(Valve Timing Control)、IECAS(Intelligent Electronic Control Adaptive Suspension)、Injector、EOP(Electrical Oil Pump) and components.

We manufactures a complete set of coil components in-house, including terminals, other stamped parts, and bobbin molding, and performs integrated in-house production from winding, spot welding, and exterior molding to resistance and impulse waveform testing.

2AIW

2EIW

2PEW

■Wire sizes

φ0.16、φ0.174、φ0.21、φ0.28、φ0.29、φ0.30、φ0.32、φ0.35、φ0.4、φ0.5

Our Machines & Facilities

【Press Machine/Stamping Machines】

| Maker | Tonnage Capacity | Quantity |

|---|---|---|

| ISIS | 25T | 1 machine |

| ISIS, KYORI | 40T | 2 machines |

| KOMATSU | 45T | 1 machine |

| ISIS, KYORI, AIDA | 60T | 3 machines |

| AIDA, SEYI | 80T | 9 machines |

| AIDA | 110T | 2 machines |

| AIDA, SEYI | 160T | 4 machines |

| AIDA | 200T | 1 machine |

| AIDA | 220T | 1 machine |

| TOTAL | 24 machines |

【Vertical Type Injection Molding Mahines】

| Maker | Tonnage Capacity | Quantity |

|---|---|---|

| NISSEI | 50T | 3 machines |

| NISSEI | 60T | 1 machine |

| Sodick, NISSEI | 75T | 8 machines |

| JSW、NISSEI | 100T | 5 machines |

| NISSEI | 150T | 2 machines |

| TOTAL | 19 machines |

【Holizontal Type Injection Molding Machines】

| Maker | Tonnage Capacity | Quantity |

|---|---|---|

| NISSEI | 30T | 1 machine |

| JSW | 55T | 2 machines |

| NISSEI | 60T | 2 machine |

| NISSEI | 80T | 2 machines |

| NISSEI | 110T | 1 machine |

| TOTAL | 8 machines |

【Measuring Instruments】

| Measuring Instruments | Quantity |

|---|---|

| 2D Tool Microscope (Mitsutoyo) | 4 machines |

| 3D Coordinate Measuring Machine (Mitsutoyo) | 2 machines |

| Rockwell Hardness Tester (Matsuzawa) | 1 machine |

| Vickers Hardness Tester (Akashi) | 1 machine |

| Contracer (Mitsutoyo) | 1 machine |

| Surface Roughness Tester (Mitsutoyo) | 1 machine |

| X-ray Plating Thickness Tester (FISCHER) | 1 machine |

【Evaluation Equipment】

| Evaluation Equipment | Quantity |

|---|---|

| Thermal Shock Chamber (ESPEC) | 1 machine |

| Temperature and Humidity Chamber (ESPEC) | 1 machine |

| Solderability Tester | 1 machine |

| Pin Hole Tester | 1 machine |

| X-ray Inspection System | 1 machine |

| XRF (HORIBA) | 1 machine |

| Salt Spray Tester | 1 machine |

【Machine Tools(For Tooling)】

| Machine Tools | Quantity |

|---|---|

| WEDM(Sodick, Fanuc) | 7 machines |

| EDM (Sodick) | 1 machine |

| Small-hole Drilling EDM (Sodick) | 1 machine |

| Surface Grinder(Okamoto) | 6 machines |

| Milling Machine (Makino、Kanto) | 5 machines |

| Machining Center(Makino、OKK) | 2 machines |

| Lathe(Takisawa) | 2 machines |

| Drilling Machine(Hitachi) | 1 machine |

| Band Sawing Machine(Tsune, Saw King) | 2 machines |

【Other Facilities】

| Other Facilities | Quantity |

|---|---|

| Ultrasonic Cleaning Machine (Hydrocarbon) | 2 machines |

| Ultrasonic Cleaning Machine (Ionized Water) | 1 machine |

| Heat Treatment Furnace | 3 machines |

| Vacuum Heat Treatment Furnace | 3 machines |

| Sand Blaster | 1 machine |

| Vibratory Barrel Finishing Machine | 3 machines |

| Rotary Barrel Finishing Machine | 2 machines |

Company Information

| Company Name | RHYTHM VIETNAM (SAIGON) CO., LTD. |

|---|---|

| Establishment | March/1995 |

| Legal Capital | 4,000,000USD |

| Business/Services |

Progressive Metal Stamping、Designing and Tooling Die、Over Molding(Insert Molding)、Assembly Barrel Plating、Reel-to-reel Plating、Vacuum Heat Treatment |

| Address | Lot AM. 34b-36-38a and Lot AN. 27b-29-31-33-35a, Road 12, Tan Thuan EPZ, Tan Thuan Ward, Ho Chi Minh City, Vietnam |

| Telephone | +84 283 770 1416 |

| FAX | +84 283 770 1415 |

| International Certification | ISO9001、ISO14001、IATF16949 |

| Land Used | Factory 1:10,000㎡ Factory 2:5,000㎡ |

| Work force | 329 employees(June/2024) |

History

| 1995 | Established and started operation |

|---|---|

| 1999 | Acquired ISO9002:1994 |

| 2002 | Inauguration of new factory |

| Acquired ISO14001:1996 | |

| 2004 | Introduced Barrel plating |

| 2005 | Acquired ISO/TS16949 |

| 2011 | Joined RHYTHM WATCH Group |

| 2012 | Established fully owned subsidiary in Hanoi (Rhythm Kyoshin Hanoi, currently Rhythm Vietnam (Hanoi) Noi Bai Branch) |

| 2018 | Acquired IATF16949 |

| Introduced Reel-to-reel plating | |

| 2020 | Became subsidiary of RHYTHM Co., Ltd. |

| 2024 | Our fully owned subsidiary Rhythm Kyoshin Hanoi has been merged by Rhythm Precision Vietnam and changed its name to Rhythm Vietnam (Hanoi) Noi Bai Branch. |

| 2025 | Changed company name from Kyoshin Vietnam Co., Ltd. to Rhythm Vietnam (Saigon) Co., Ltd. |

Valued Customers

・NIDEC POWERTRAIN SYSTEMS Gr.

・HARADA INDUSTRY Gr.

・MARELLI Gr.

・NIPPON SEIKI

・RYOSHO

・JABIL

・HITACHI ASTEMO

・TAKAKO

・MITSUBA Gr.

・NAKAMURA ELECTRIC

・DENSO

・ARION ELECTRIC

・KYOKUTO ELECTRIC

・MINEBEA ACCESS SOLUTIONS

・YAMAHA MOTOR ELECTRONICS

Our Sustainability Approach

Our company operates in compliance with environmental regulations established by the Vietnamese government and has obtained the necessary environmental license.

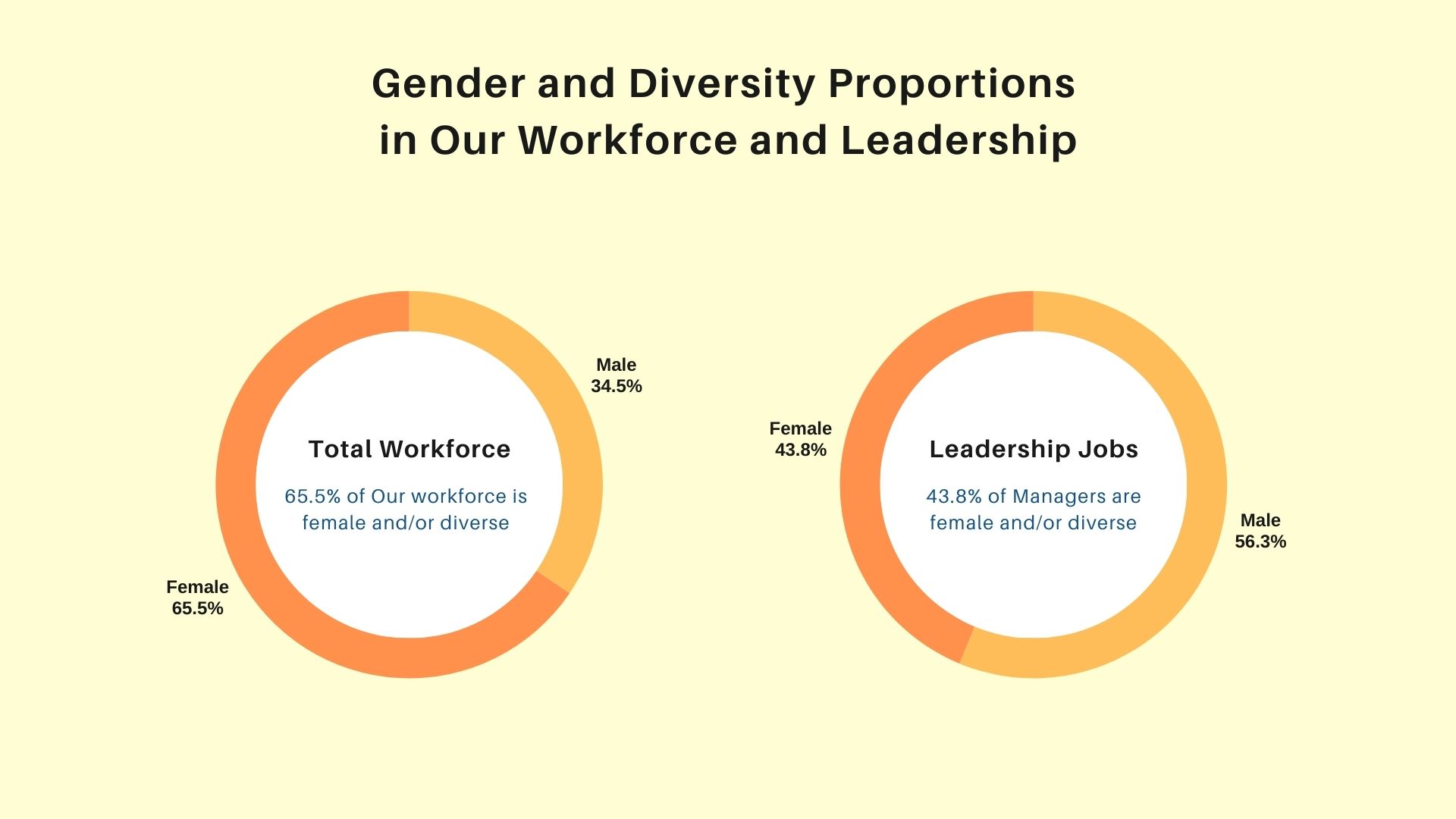

Moreover, 44% of our management positions are held by female and/or diverse individuals. This is a pivotal achievement in our ongoing efforts to shatter gender barriers and champion equality in leadership.

We remain dedicated to these principles and continually strive to create an environment where every individual feels respected and empowered to succeed.