RHYTHM VIETNAM (HANOI) CO., LTD. NOI BAI BRANCH(RVHN):IZ

Rhythm Vietnam (Hanoi) Co., Ltd. Noi Bai Branch (Ex. Rhythm Kyoshin Vietnam Co., Ltd.) was established in 2012 as a subsidiary

of Kyoshin Vietnam Co., Ltd.(KVC).

In the north part of Vietnam, since there are many motorcycle parts

makers resistered as IZ company, We operate as IZ company too.

This helps our customer (resistered as IZ company) to minimize their

importing works or import tariffs.

In addition, established in Hanoi enables delivery date to shorten and

even if quolity matter happens, we can handle it promptly.

Our main products are used in automobiles and motorcycles though,

we also manufacture products for various kind of field for example

office appliance, fire equipment, musical instruments.

of Kyoshin Vietnam Co., Ltd.(KVC).

In the north part of Vietnam, since there are many motorcycle parts

makers resistered as IZ company, We operate as IZ company too.

This helps our customer (resistered as IZ company) to minimize their

importing works or import tariffs.

In addition, established in Hanoi enables delivery date to shorten and

even if quolity matter happens, we can handle it promptly.

Our main products are used in automobiles and motorcycles though,

we also manufacture products for various kind of field for example

office appliance, fire equipment, musical instruments.

Our Business

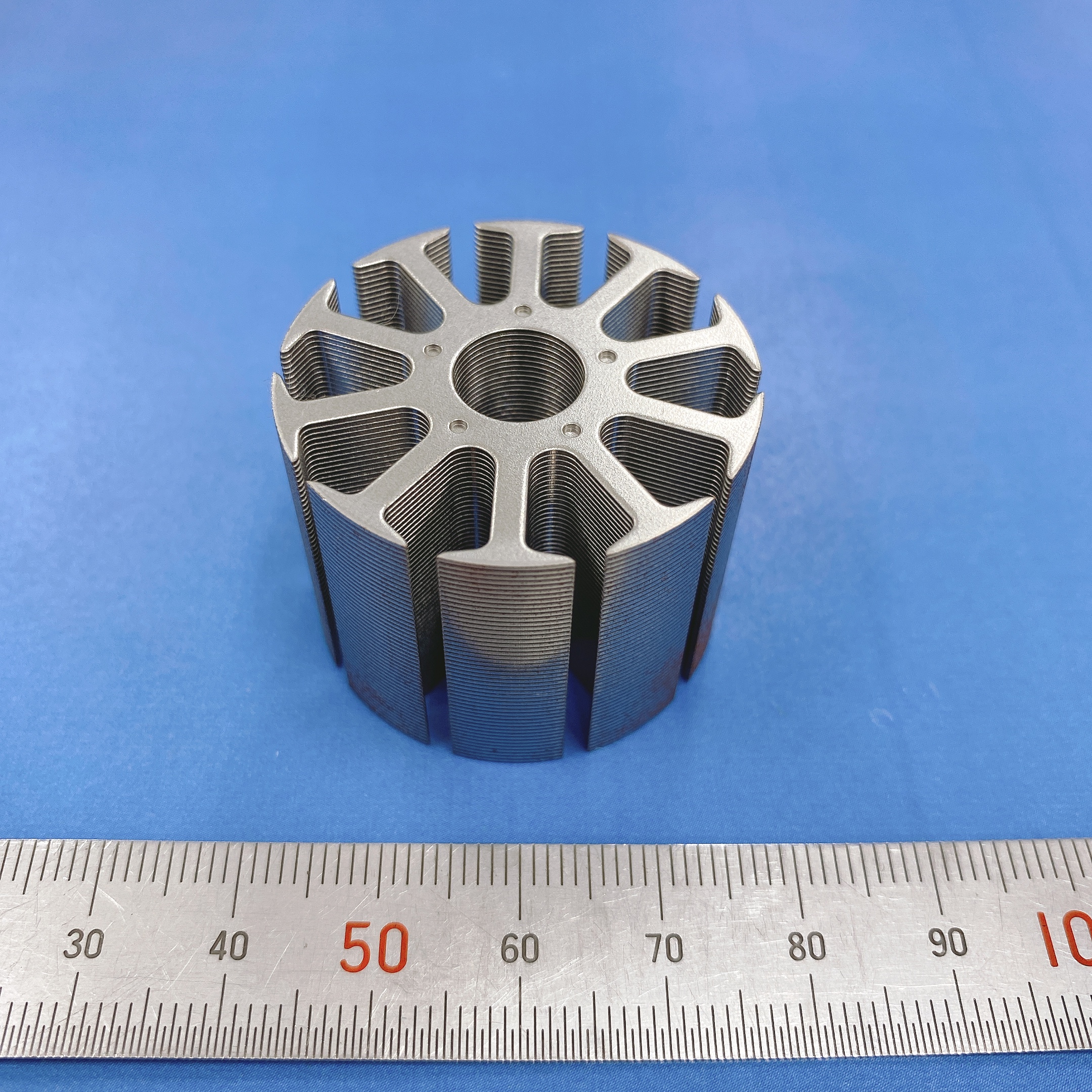

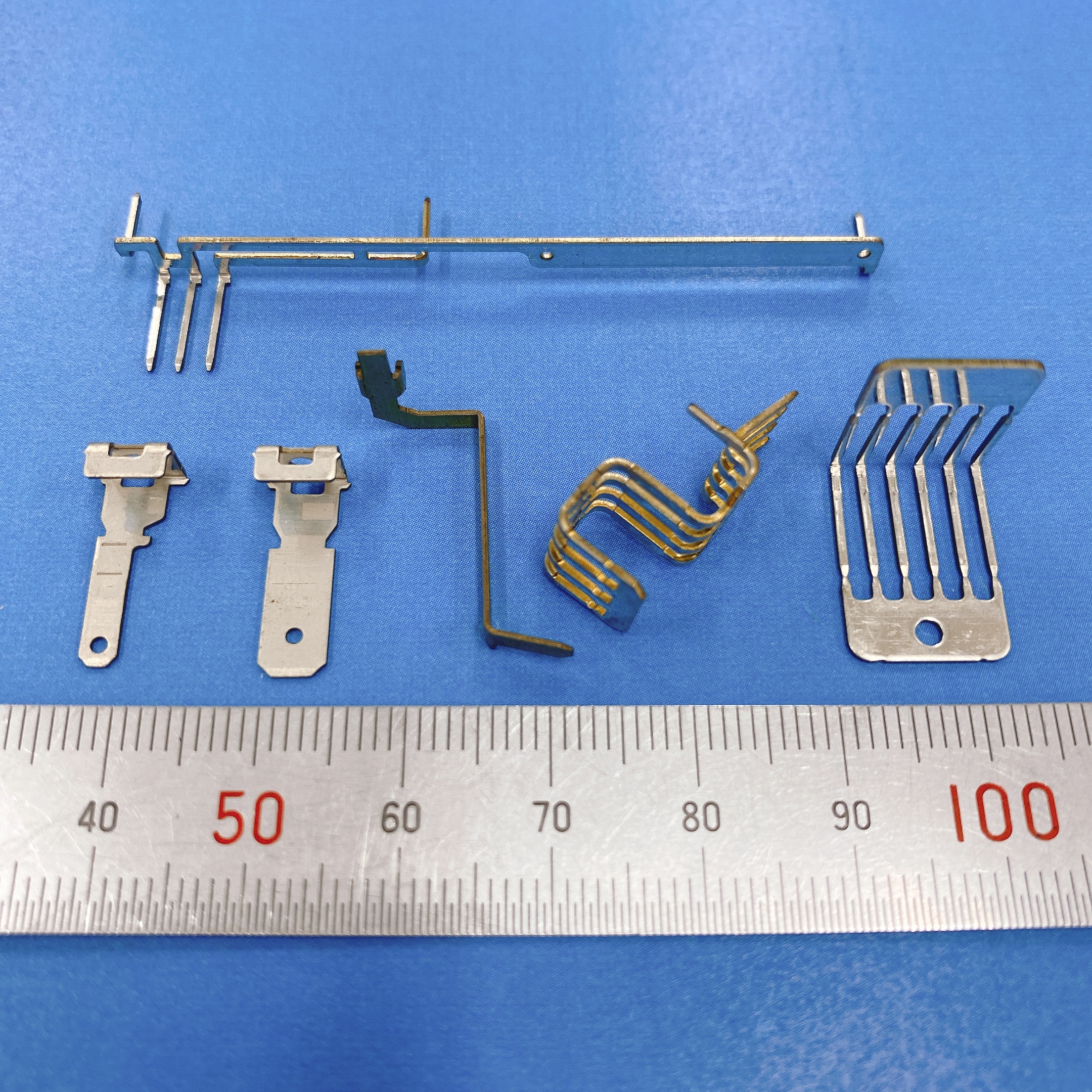

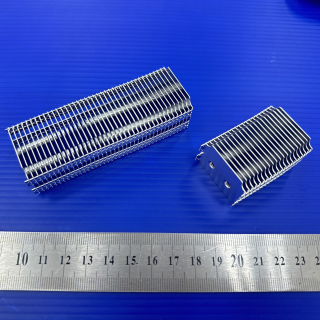

【Progressive Metal Stamping Parts】

■Designing and Building mold : RKH factory

■Quantity:25 machines (45t~160t)

■Process Type:Punching, Bending, Drawing etc...

※Tapping and Inserting in progressive die is available‼

■Material thickness:0.5~3.5t

■SPM:30~800

■Die height:155~360

■Mold size:~650×1560

■Raw Material of Products

Cold rolled steel、Electro-galvanized cold rolled steel、ZAM、Silicon Steel、Soft Magnetic Iron、Aluminium、Stainless Steel、

Brass、Phosphor Bronze、Copper、Corson Alloy etc....

(Bare materials /Sn, Au or Ag plated materials)

■Raw Material Maker(direct or indirect)

Nippon Kinzoku(Japan), CSVC(China Steel Sumikin Vietnam),

JFE Steel(Japan), Nippon Steel(Japan), Kobe Steel(Japan),

Mitsui Sumitomo Metal Mining(Japan), Mitsubishi Material(Japan),

JX Metal(Japan), Harada Metal(Japan),

POSCO(Vietnam/Korea), Minchali(Taiwan), First Copper(Taiwan), Lee Ku(Korea)

■Product samples

■Surface Treatment

Reel to reel Plating:Cu、Ni、Sn(KVC)

Barrel Plating:Cu、Ni、Sn(KVC)、Electroless Ni Plating(Outsource)、Zn Chromate(Outsource)

Hanger(Rack) Plating:Zn Chromate、Electroless Ni Plating (Outsource)

Cation ED Coating (Outsource)

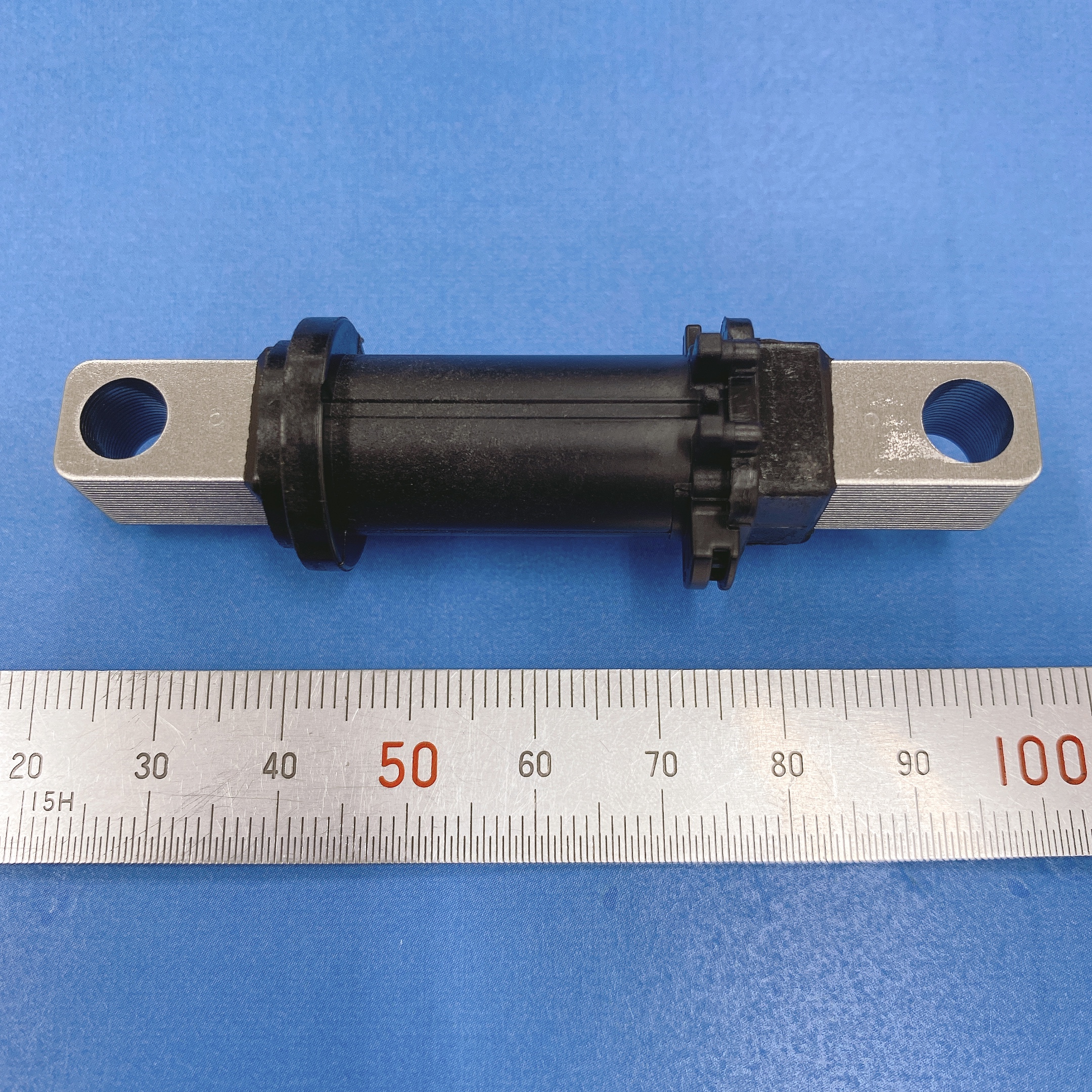

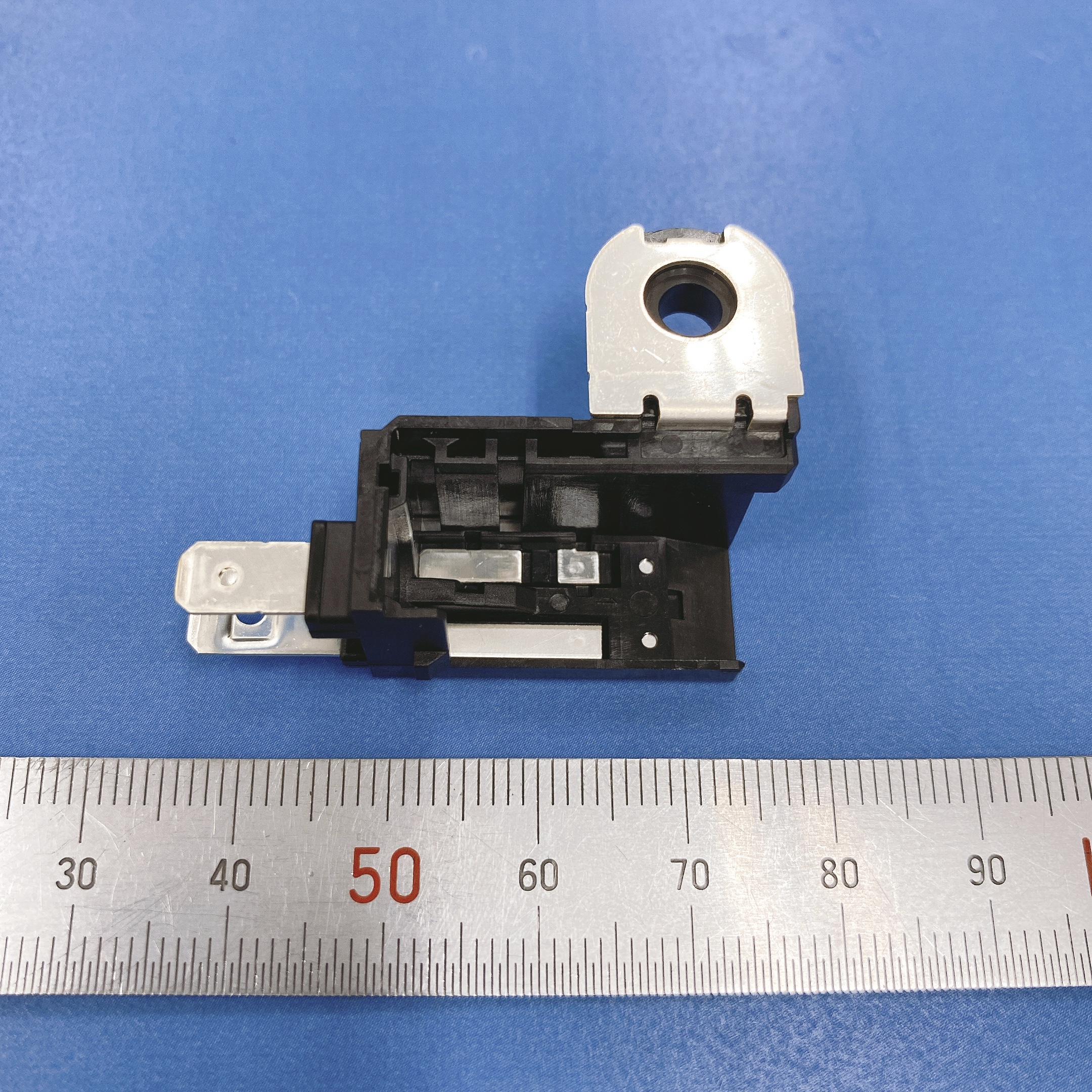

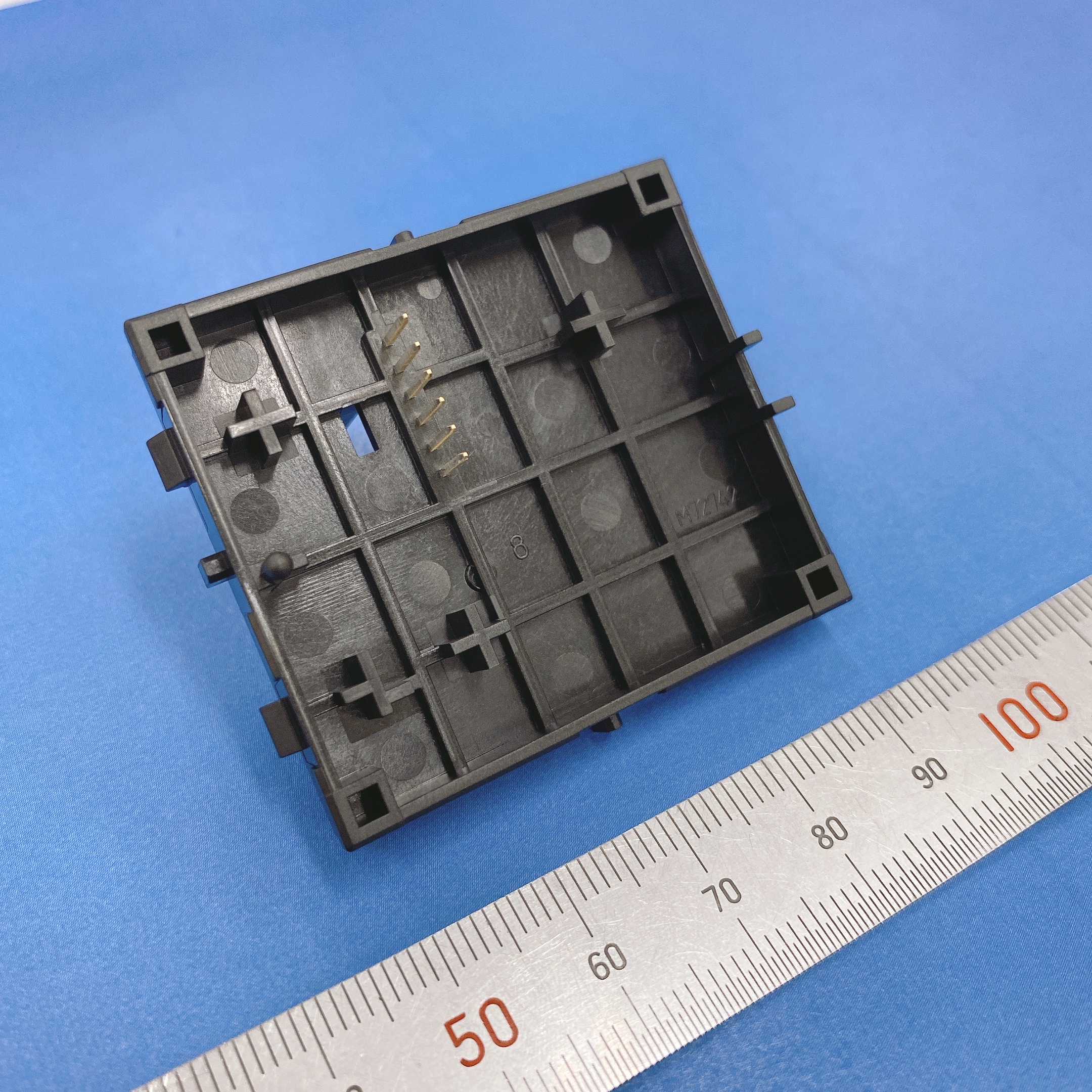

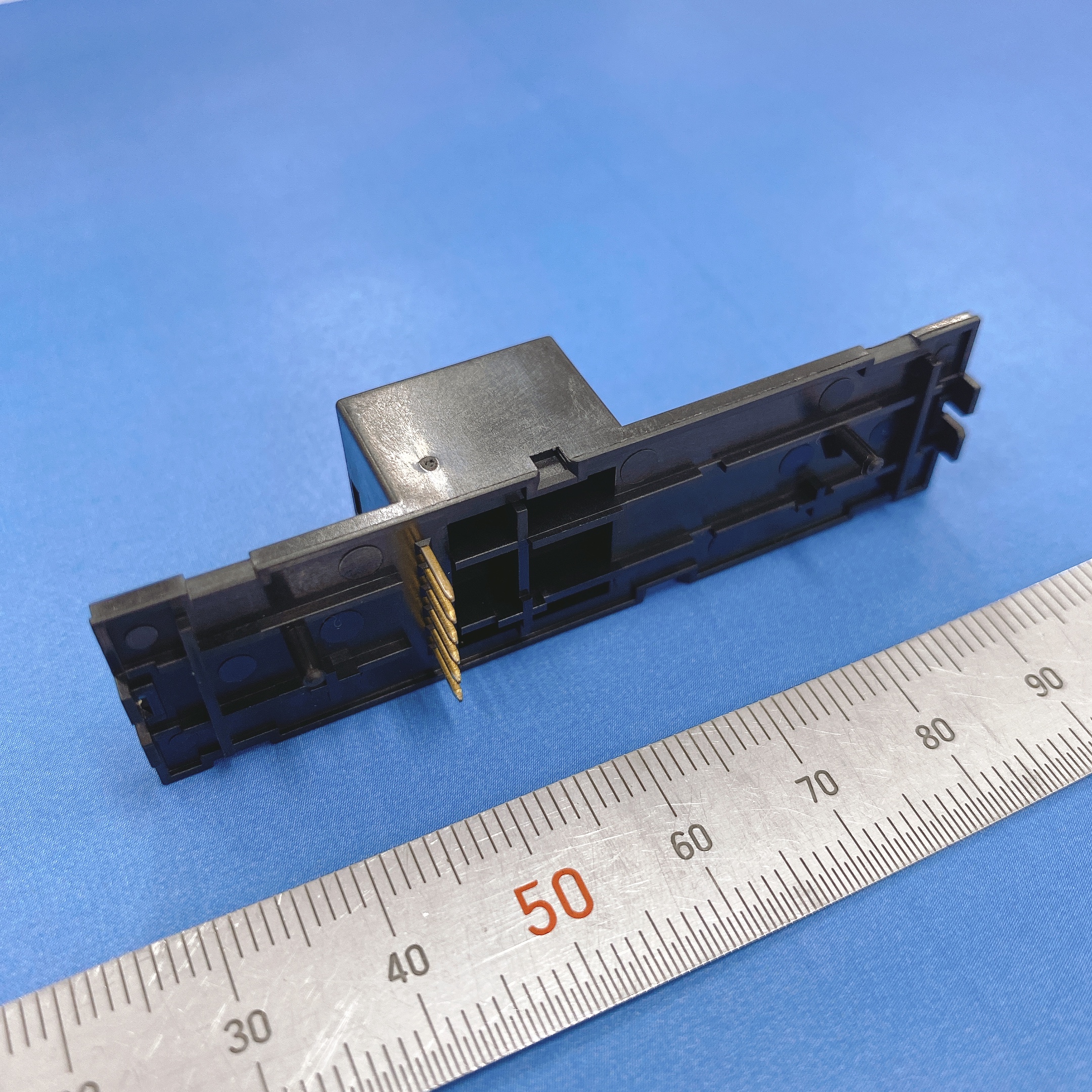

【Insert Molding】

We perform over molding by using our own stamping work.

We have a total 7 vertical injection molding machines ranging from 40 to 75 tons.

■Product samples

-

-■Raw material of products

PA6, PA66, POM, PBT, ABS

Our Machines & Facilities

【Press Machines/Stamping Machines】

| Maker | Tonnage Capacity | Quantity |

|---|---|---|

| SEYI | 45T | 4 machine |

| KYORI | 60T | 1 machine |

| AIDA,SEYI | 80T | 11 machines |

| ISIS | 100T | 1 machine |

| AIDA | 110T | 1 machine |

| AIDA, SEYI | 160T | 7 machines |

| Total | 25 machines |

【Insert Molding Machine】

| Maker | Tonnage Capacity | Quantity |

|---|---|---|

| JSW | 40T | 1 machine |

| NISSEI | 75T | 6 machines |

| Total | 7 machines |

【Measuring Instruments】

| Measuring Instruments | Quantity |

|---|---|

| Microscope(Mitutoyo) | 4 machines |

| Hardness inspection machine(Mitutoyo) | 1 machine |

| Contour inspection machine(Mitutoyo) | 1 machine |

| CMM(Mitutoyo) | 1 machine |

| Push-Pull Gauge(Imada) | 1 machine |

| Image inspection machine(Keyence) | 1 machine |

【Evaluation Equipment】

| Evaluation Equipment | Quantity |

|---|---|

| XRF (X-ray Inspection System) | 1 machine |

Notice:

KVC can help RKH to evaluate even if RKH doesn't have specific equipmemt .

【Machine Tools (For Tooling)】

| Machine Tools | Quantity |

|---|---|

| WEDM(Sodick) | 2 machines |

| Small-hole Drilling EDM(Sodick) | 1 machine |

| Milling machine(Makino) | 1 machine |

| Lathe(Takizawa) | 1 machine |

| Surface Glinder(Okamoto) | 5 machines |

【Other Facilities】

| Other Facilities | Quantity |

|---|---|

| Ultrasonic Cleaning Machine (Hydrocarbon) | 2 machines |

| Ultrasonic Cleaning Machine (Ionized Water) | 2 machines |

| Vibratory Barrel Finishing Machine | 1 machine |

| Rotary Barrel Finishing Machine | 1 machine |

Company Information

| 会社名 | RHYTHM VIETNAM (HANOI) CO., Ltd. Noi Bai Branch |

|---|---|

| 設立 | September/2012 |

| 資本金 | 7,500,000USD |

| 事業内容 | Progressive Metal Stamping, Designing and Tooling Die, Insert Molding |

| 住所 | Plot 69A1&69A2, NoiBai IZ, Mai Dinh commune, Soc Son Distict, Hanoi. |

| 電話 | +84 243 582 4637/4638 |

| FAX | +84 243 582 4639 |

| 認証 | ISO9001, ISO14001, IATF16949 |

| 敷地面積 | 10,000㎡ |

| 従業員数 | 194 employees(Apr/2024) |

会社沿革

| 2012年 | Established |

|---|---|

| 2013年 | Started operation |

| 2015年 | Acquired ISO9001:2015 and ISO14001:2015 |

| 2019年 | Built a second factory(October) |

| 2020年 | Acquired IATF16949(March) |

| Became subsidiary of RHYTHM Co., Ltd. | |

| 2024年 | Rhythm Kyoshin Hanoi merged with neighboring group company Rhythm Precision Vietnam and change its name to Rhythm Vietnam (Hanoi) Co., Ltd. Noi Bai Branch. |

主な取引先

・TOYODENSO VN

・HAMADEN VN

・HITACHI ASTEMO VP

・YAMAHA MOTOR ELECTRONICS

・YOKOWO VN

・DENSO VN

・FUKOKU VN

・NIPPON SEIKI VN

・MINEBEA

・FUJIPLA VN

・ARAI VN

・SATO VN

・KORG